Our Applications Cover Diverse Corporate Markets

Additive Manufacturing, Done Right

From rapid prototyping to short-run production, we design and manufacture functional parts using industrial-grade additive processes. Built in Decatur, Alabama. Trusted across automotive, aerospace, medical, and industrial sectors.

Industrial Additive Manufacturing & Product Development

We specialize in large-format and production-grade 3D printing, patternmaking, and applied engineering support for companies that need parts that work, not just renderings.

Production-Grade Additive

We specialize in large-format and production-grade additive manufacturing using industrial machines and materials intended for functional use, not display models.

Applied Engineering Support

Our work integrates CAD, materials knowledge, and manufacturing constraints to ensure printed parts are suitable for real-world loads, environments, and downstream processes.

Adaptable Manufacturing

Whether you need a single prototype, tooling, patterns for casting, or a short production run, we tailor the process to fit schedule, budget, and technical requirements.

Why Choose Jaegertech?

Production-Grade Additive Manufacturing

We focus on parts designed for real use, with attention to strength, accuracy, and material performance.

Large-Format Specialists

Our expertise is in full-scale parts, tooling, and patterns that exceed standard printer capabilities.

Engineering-Led Approach

Design, materials, and process decisions are driven by function and manufacturing realities.

Patternmaking & Tooling Experience

Proven experience supporting casting, fixtures, and industrial manufacturing workflows.

In-House, Hands-On Execution

All work is performed by the team operating the equipment.

JaegerTech has supported and completed projects spanning the medical, aerospace, automotive, foundry, educational, equine veterinary, and consumer goods sectors, applying additive manufacturing where function and reliability matter.

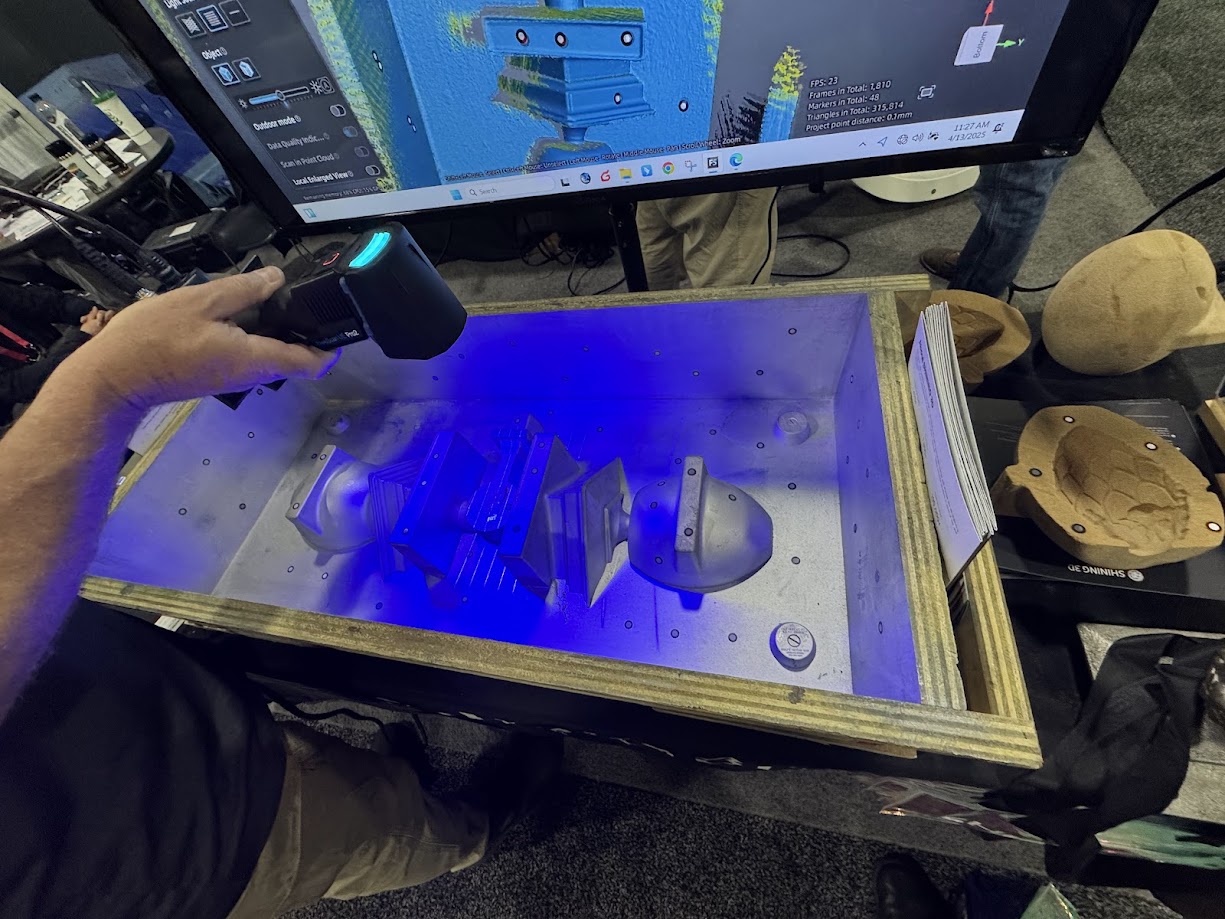

Patternmaking for Modern Foundries

Our patternmaking work combines traditional foundry principles with large-format additive manufacturing to support sand casting, tooling, and short-run production.

Old-world craftsmanship with modern tools.

We design and produce 3D-printed patterns, molds, and tooling for sand casting and related processes, with attention to draft, shrinkage, and foundry requirements.

3D Printing CNC Machine Tool Organizers: A Game-Changer for Efficiency and Precision In the fast-paced world of CNC machining, organization is key to maximizing efficiency and minimizing errors. The tools of the trade—collets, drill bits, end mills, and other precision tools—demand a system that keeps them readily accessible, protected, and correctly placed. Enter 3D-printed tool

The Benefits of 3D-Printed Alignment Jigs for Decal and Drill Hole Placement Precision is key in both professional manufacturing and DIY projects, especially when it comes to tasks like applying decals or manually drilling holes. Misaligned decals can ruin the appearance of a product, while incorrectly drilled holes can compromise its functionality. Traditional alignment tools